Vous êtes-vous déjà demandé comment un sac imperméable pouvait survivre à des rafales de nuages et à des eaux vives sans la moindre couture ? La réponse est le soudage à haute fréquence (HF), la technologie de base de notre usine chinoise. Au lieu de percer des trous avec des aiguilles, nous fusionnons le film TPU en une seule feuille solide, créant ainsi un joint qui est en fait plus résistant que le matériau lui-même.

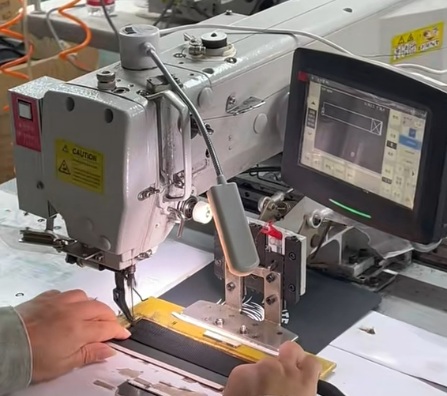

Que se passe-t-il à l'intérieur de la machine ?

- Deux panneaux de TPU sont placés entre des électrodes de cuivre de précision.

- Un champ électromagnétique de 27,12 MHz fait vibrer les molécules polaires, générant une chaleur instantanée et localisée (≈ 200 °C) en moins d'une demi-seconde.

- La pression simultanée (5-8 bar) force les chaînes de polymères mues à s'emboîter.

- La soudure se refroidit sous la pince, formant un joint continu et sans soudure - pas de colle, pas de points de suture, pas de points faibles.

Pourquoi les importateurs spécifient-ils le soudage HF ?

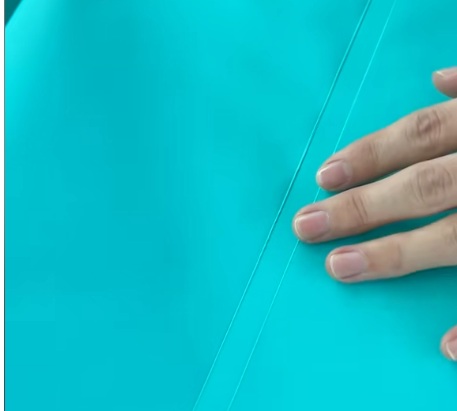

- Indice d'étanchéité: IPX-7 directement à partir du poste de soudure - 30 minutes d'immersion, aucune pénétration.

- Résistance mécanique: Valeur de pelage ≥ 300 N/5 cm ; lorsque nous tirons pour casser, le tissu se déchire avant la couture.

- Esthétique soignéeLes produits de la catégorie "Produits de la mer" sont des produits de la catégorie "Produits de la mer" : bords droits, panneaux transparents, logos gravés au laser - prêts pour la vente au détail dès la sortie de la presse.

- Économie de poidsLe poids du produit fini est réduit de 8 à 12 %, ce qui permet de réduire les frais de transport.

Des kayaks aux rayons des épiceries

Notre production quotidienne comprend des sacs secs à roulettes, des sacs à dos réfrigérants souples, des pochettes médicales et des sacs de pêche en bandoulière, tous soudés, testés à l'étanchéité et expédiés sous un même toit. Avec 18 stations HF, nous pouvons produire 60 000 pcs/mois, MOQ 300 pcs/style et 30 jours de délai FOB pour les clients de l'UE et des États-Unis.

Tester la technologie libre

Envoyez-nous votre logo ; nous souderons deux échantillons A4 et vous les enverrons en moins d'une semaine - pas de frais de moule, pas de MOQ. Voyez par vous-même pourquoi la fusion est plus efficace que la couture, et donnez à votre marque une couture qui ne fuira jamais.

Contactez-nous dès aujourd'hui pour un devis rapide ou une visite virtuelle de l'usine.