Ever wondered how a waterproof bag can survive cloud-bursts and white-water without a single stitch? The answer is high-frequency (HF) welding, the core technology in our Chinese factory. Instead of punching holes with needles, we fuse TPU film into one solid sheet, creating a joint that is actually stronger than the material itself.

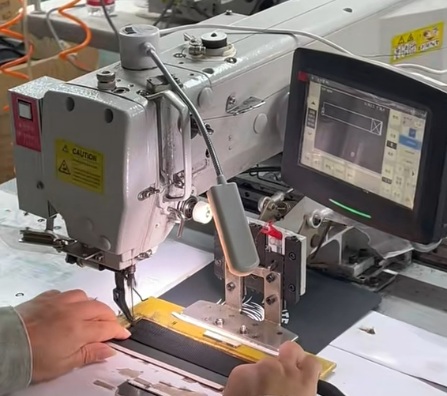

What happens inside the machine?

- Two TPU panels are placed between precision copper electrodes.

- A 27.12 MHz electromagnetic field vibrates the polar molecules, generating instant, localised heat (≈ 200 °C) in less than half a second.

- Simultaneous pressure (5–8 bar) forces the molled polymer chains to inter-lock.

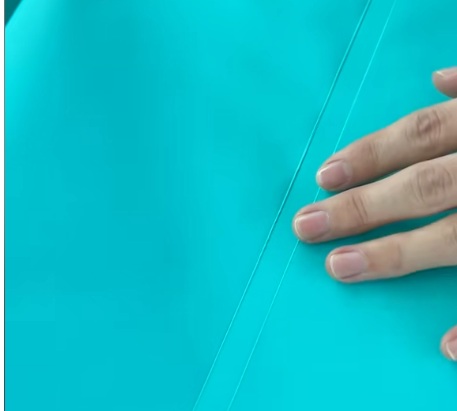

- The weld cools under clamp, forming a continuous, seamless seal—no glue, no stitch holes, no weak points.

Why importers specify HF welding

- Waterproof rating: IPX-7 straight off the weld jig—30 min submersion, zero ingress.

- Mechanical strength: Peel value ≥ 300 N/5 cm; when we pull to break, the fabric tears before the seam.

- Clean aesthetics: razor-straight edges, transparent panels, laser-etched logos—retail-ready out of the press.

- Weight saving: losing seam tape and reinforcement patches trims 8–12 % from finished weight, cutting your freight cost.

From kayaks to grocery aisles

Our daily output covers roll-top dry bags, soft cooler backpacks, medical pouches and fishing sling packs—each welded, leak-tested and shipped under one roof. With 18 HF stations we can produce 60 000 pcs/month, MOQ 300 pcs/style and 30-day FOB lead-time for EU/US customers.

Test the technology—free

Send us your logo; we’ll weld two A4 samples and express them to you in under a week—no mould fee, no MOQ. See for yourself why fusion beats stitching, and give your brand a seam that never leaks.

Contact us today for a fast quotation or virtual factory tour.