Your Trusted Cooler Bag Manufacturer for Insulated Excellence

We Design And Supply Soft Cooler Bags From China

As a professional cooler bag manufacturer

Founded in 1992, COOLER MAX has grown into a large cooler bag manufacturer with a 20,000 square meters factory and 400 employees. We implement advanced automated equipment like hydraulic pressure cutting machines and laser cutting machines to ensure efficient production. Our daily output reaches up to 3,000 cooler bags and annual output exceeds 1 million cooler bags and 1.5 million other bags.

Feature Products

Unique Edge as Top Cooler Bag Manufacturer

Dedicated Cooler Bag Manufacturer

Obtained certifications from BSCI, ISO, SEDEX, SGS and Intertek, With annual sales of USD 20 million, and have a stable financial position

Strong R&D Capability

Established a professional cooler bag manufacturer R&D team,own 20 utility model patents and 6 design patents

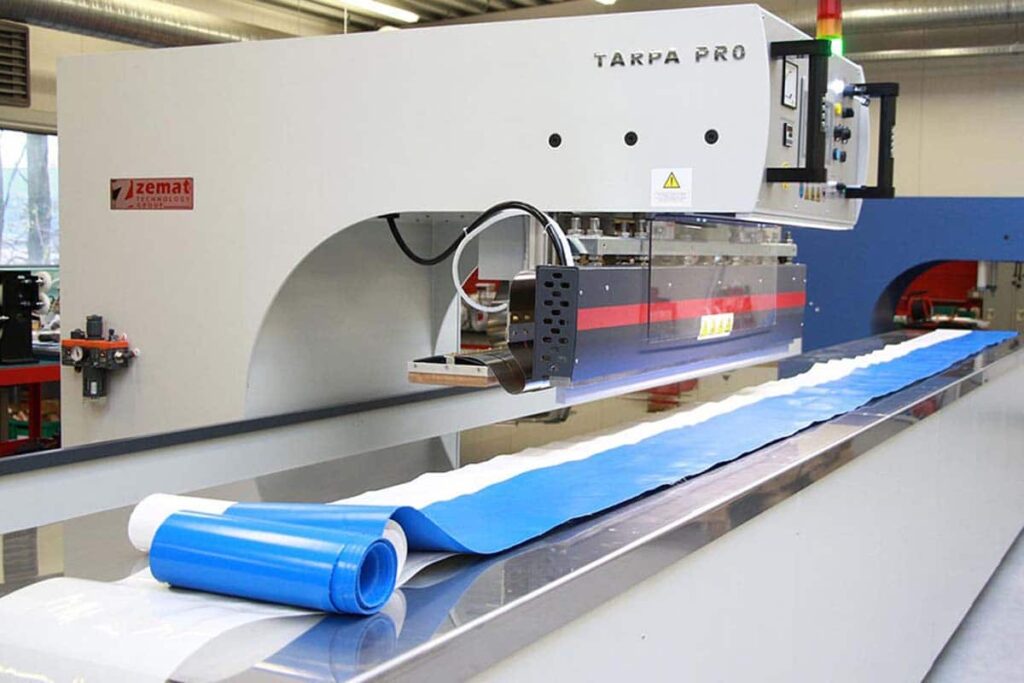

Advanced Equipment

Have 10 hydraulic pressure cutting machines and 10 laser cutting machines

Outstanding Customer Service

Have a professional customization consulting team and a 24/7 customer service team to provide you with all-around support

Advanced Technology

Adopting high frequency welding technology for higher quality and durability cooler bags for you

Large-Scale Production Capacity

The daily output of 3,000 cooler bags, Annual output of 1 million cooler bags and 1.5 million other welded bags

Process of insulated cooler bag factory

1. Contact Manufacturer

Initial contact us to discuss about product needs, preferred styles via email and phone call

2. Select Style

Customer provides images or samples of desired products, logo designs to confirm and finalize choice

3. Confirmation

Cooler bag manufacturer confirms logo design and provides price quote and production timeline

4. Make And Send Samples

Customer pays fee for cooler bag manufacturer to produce physical samples for customer approval and feedback

5. Confirm Customization

Deposit is made to cooler bag manufacturer purchase materials and components to start custom production

6. Factory Production

Manufacturer’s quality team closely inspects on the entire assembly process to deliver products with top quality

7. Settle Balance

Remaining payment is made within mutually agreed payment terms prior to product delivery

8. Shipment

The manufacturer ships finished products. Shipment is tracked to ensure successful arrival on schedule

Manufacturing Process

1. Prepare Raw Materials

2. Laser Cutting

3. High Frequency Welding

4. Heat Pressing

5. Air Tightness Tester

6. Packing

Advantages of Waterproof Zippers in Cooler Bag Manufacturing

Waterproof, heat-resistant, and flexible zipper tooth belts and puller materials, commonly made of plastic or rubber, give coolers with this zipper higher waterproofing and insulation. The double-layer or back-to-back zipper structure ensures a good sealing effect. The preference for spherical or interlocking tooth shapes provides excellent sealing at the biting points. Smooth and tight zipper edges reduce gas leakage, ensuring the highest level of sealing for cooler bags and maintaining bag quality.

Advantages of High-Frequency Welding Technology in Cooler Bag Making

High-frequency technology rapidly generates a substantial amount of heat, significantly improving production efficiency and allowing for more effective manufacturing of products. The heat produced by high frequency penetrates materials, forming a strong bond and making the bonding of cooler bags produced using this technology more robust. This technology, by concentrating heat in a short time, prevents material deformation caused by prolonged heating, enhancing the durability of cooler bags. It also contributes to a more exquisite appearance, elevating the overall quality of the product.

Custom Cooler Bags With Easy

At Coolr MAX, We turn complex Into Simple! Follow the following 3 steps to start today!

1 Tell Us What You Need Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

2 Get Solution & Quote We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 24 hours.

3 Approve for Mass Production We will start mass production after getting your approval and deposit, and we will handle the shipment.