Medical Isothermal Bags Manufacturer from China

Get medical isothermal bags with low MOQ

As an expert manufacturer, offering high-quality Custom medical isothermal bags to enhance your field

Larger Capacity, Better Price

With an existing factory area of over 30,000 square meters and more than 300 employees, our annual output value reaches 140 million yuan.

Lower MOQ, More Flexibility

Save more and increase profitability with a minimum order quantity starting from 200

More Reliable, More Comfortable

The material of the bags should be durable and environmentally odorless, ensuring long-term durability and a pleasant user experience.

Medical Isothermal Bags

What Set Us Top of Other Manufacturers

Strong Capacity

With the support of our proficient R&D team, we have successfully obtained 20 utility model patents and 6 design patents, showcasing our commitment to innovation and creativity.

Well-equipped

Equipped with 180 professional high-frequency machines, 12 laser cutting machines, over 30 computerized pattern machines, and supplemented by various related testing instruments.

Favorable Price

Up to 10% lower raw material costs contributed by bulk order needs and stable supply guaranteed by professional manufacturing process, make it possible for our lower price.

Full support & service

From pre-sales to manufacture and after-sales, we will provide the tailored solution according to your design and quote within 24 hours.

Customization Process

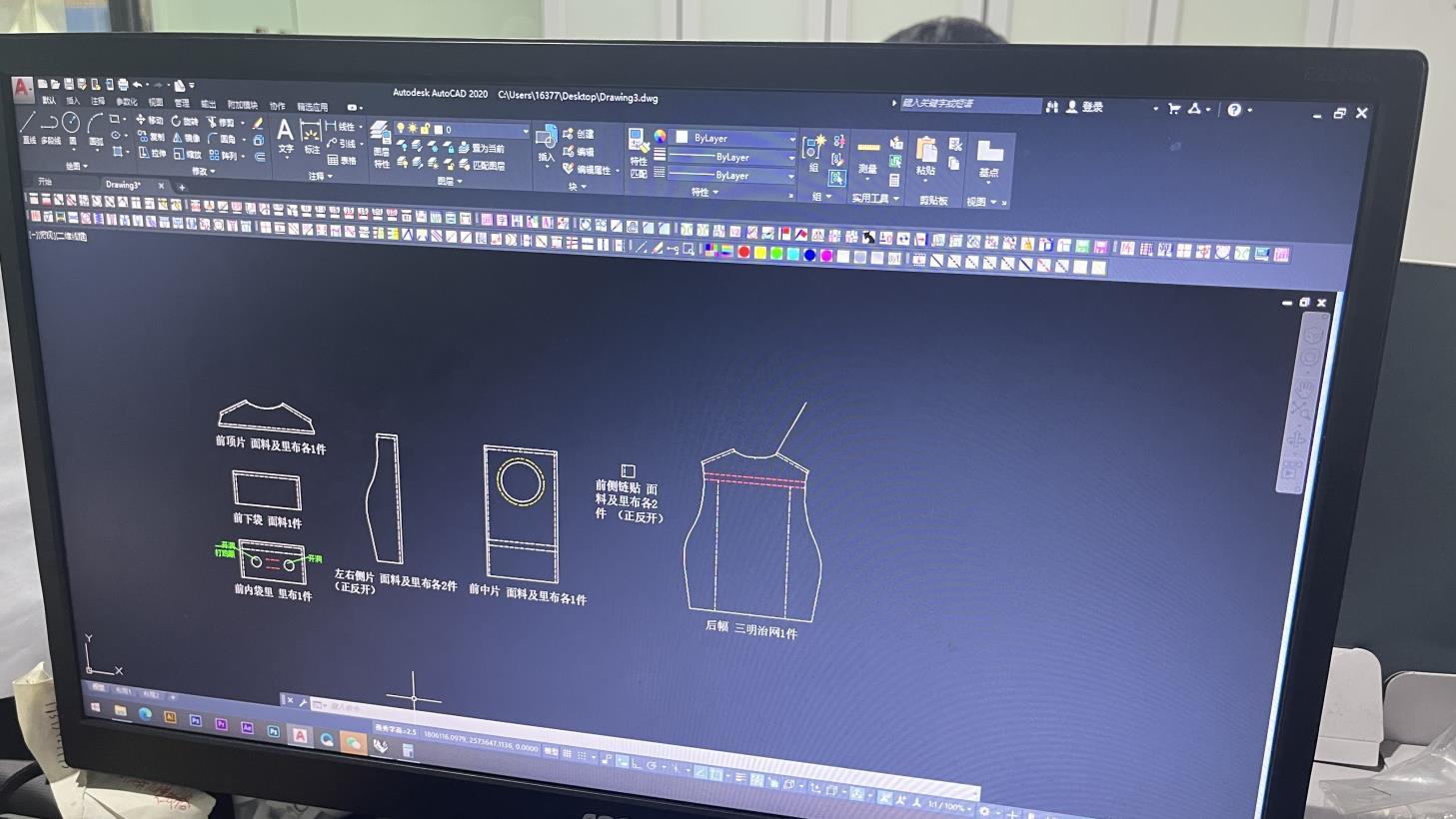

Design Selection

Customers provide or choose the style of medical insulation bags, including design patterns and logo styles, to determine the initial design direction of the product.

Design Confirmation

Customers communicate with the factory regarding logo styles and quotations to ensure both parties have a common understanding of the product’s cost and design.

Sample Production

After the customer pays the sampling fee, the factory will produce samples for the customer to inspect whether they meet the design and quality requirements.

Sample Confirmation

Customers carefully inspect the samples to confirm if they meet the requirements, before deciding whether to proceed to the mass production stage.

Production and Delivery

After confirming the samples are correct, customers pay the deposit, and the factory begins mass production. After production completion, arrangements are made for shipment, along with necessary after-sales services.

Manufacturing Process

1. Prepare Raw Materials

2. Laser Cutting

3. High Frequency Welding

4. Heat Pressing

5. Air Tightness Tester

6. Packing

Custom Medical Isothermal Bags With Easy

At Coolr MAX, We turn complex Into Simple! Follow the following 3 steps to start today!

1 Tell Us What You Need Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

2 Get Solution & Quote We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 24 hours.

3 Approve for Mass Production We will start mass production after getting your approval and deposit, and we will handle the shipment.